High Reliability

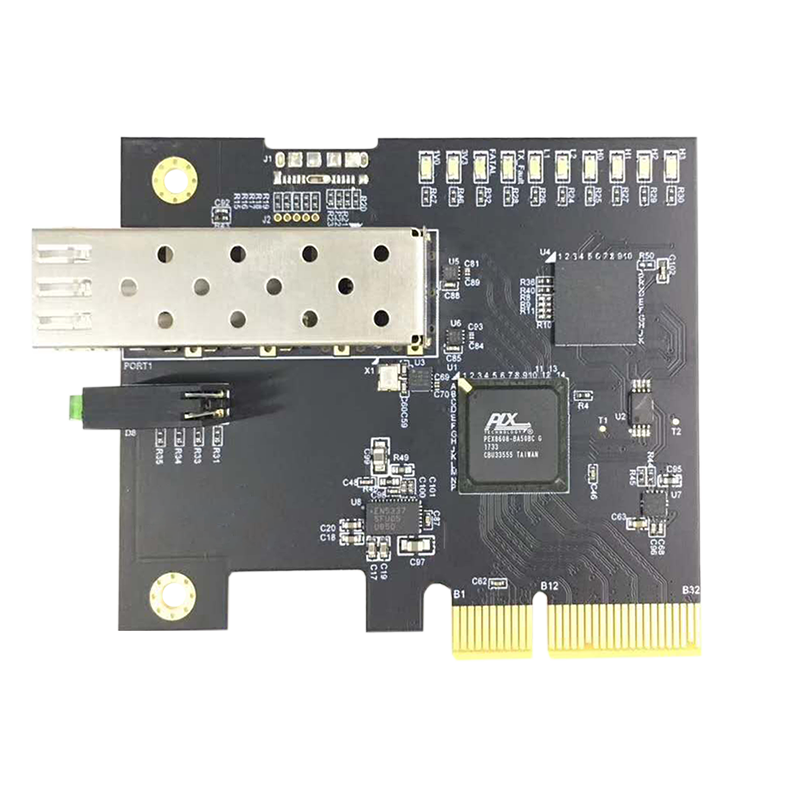

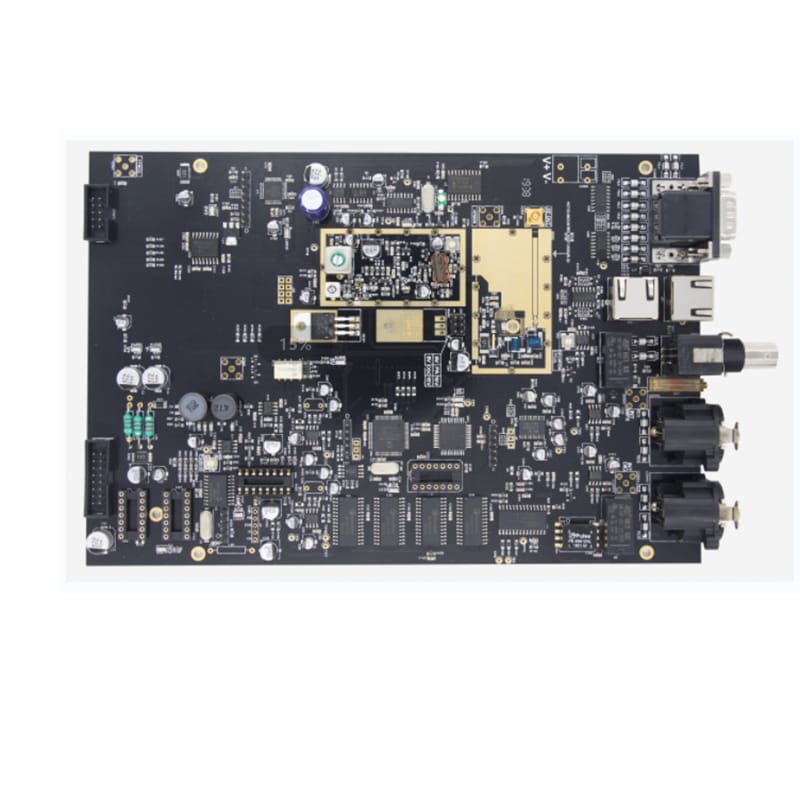

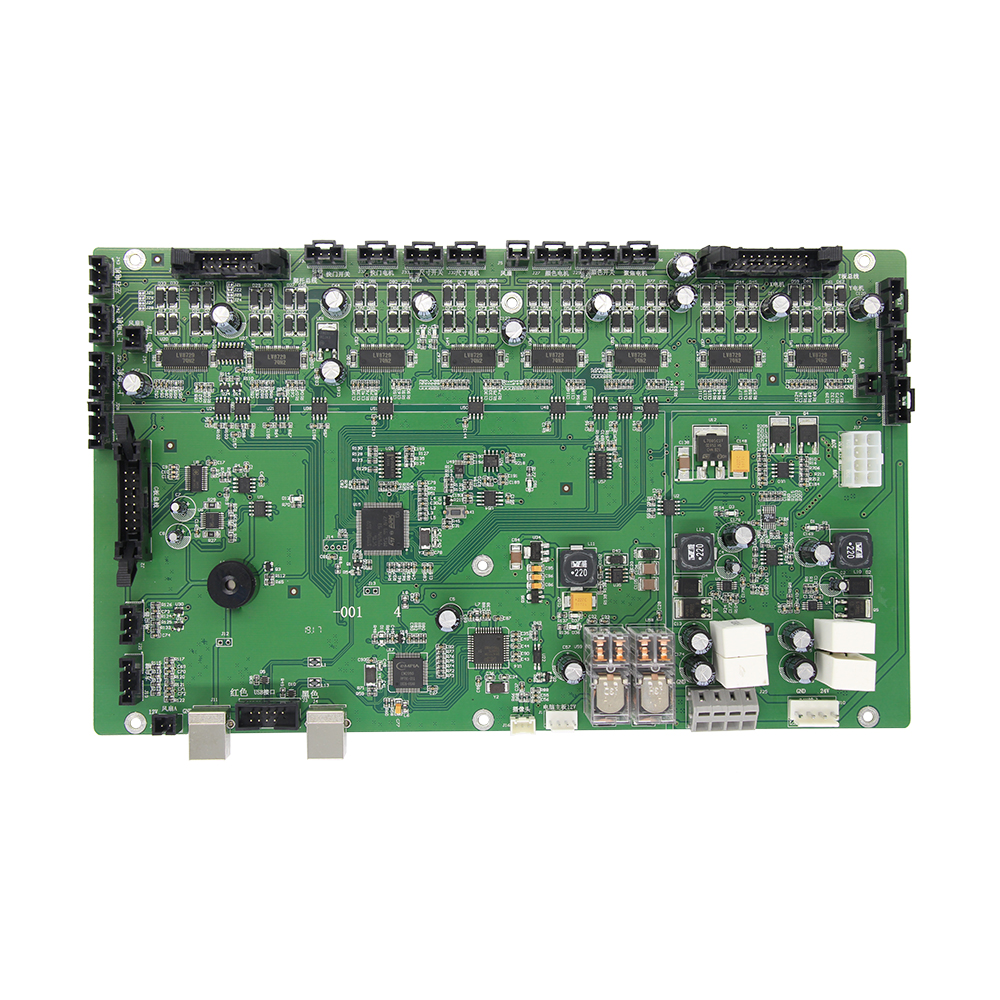

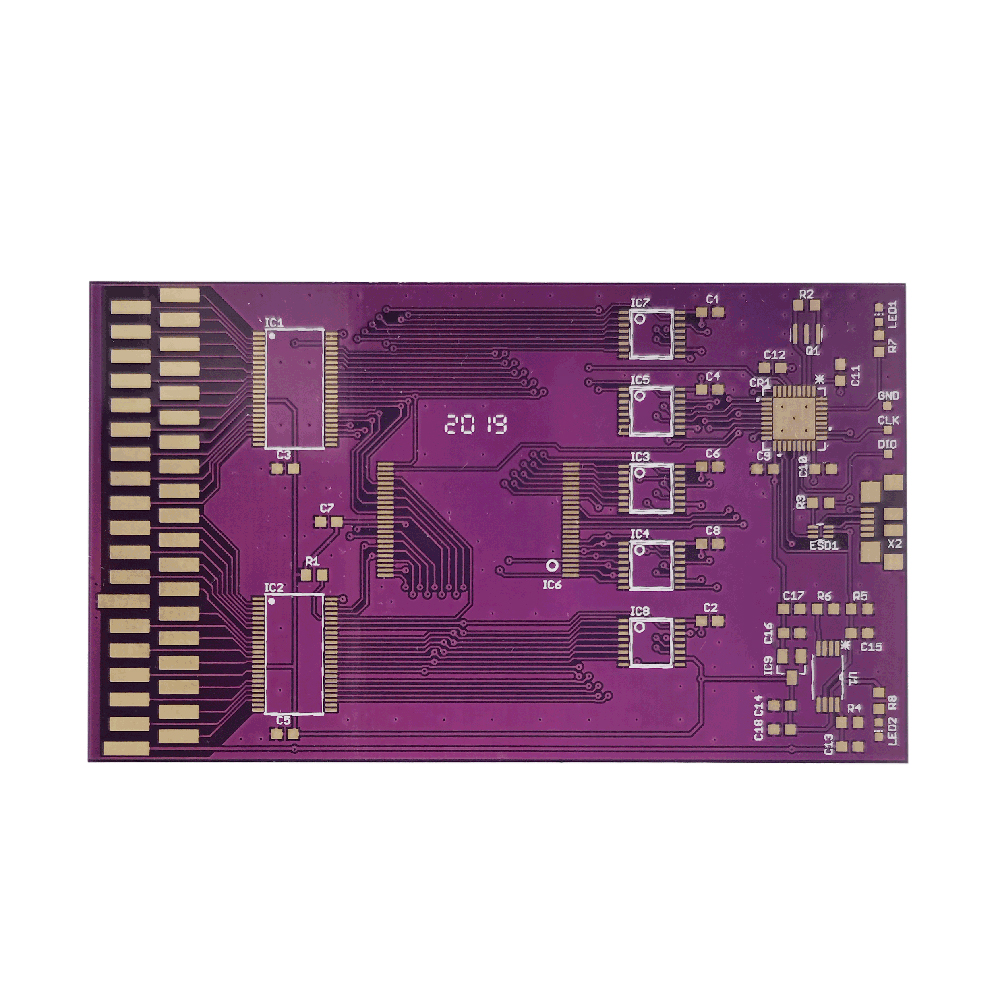

Photoplate: Using photoplate technology to transfer circuit patterns onto a substrate. Excess copper material is removed by photomask and chemical etching to form the desired circuit pattern. Gold-plated treatment: Gold-plated treatment is carried out on the gold finger part to improve its electrical conductivity and corrosion resistance. Usually, the electroplating method is used to uniformly deposit the metal material on the surface of the gold finger. Welding and assembly: Weld and assemble the components and PCB board to ensure that the solder joints are firm and reliable. Use surface mount technology (SMT) or plug-in soldering technology, choose according to specific requirements. Quality inspection and testing: Strict quality inspection and testing are carried out during the production process to ensure that the golden finger PCB board meets the specifications and quality requirements.Flexible Customization

Including visual inspection, electrical characteristic test, contact impedance test, etc. Cleaning and coating: Clean the finished Goldfinger PCB to remove surface dirt and residues. Anti-corrosion coating treatment is carried out as required to improve the corrosion resistance of the PCB board. Packaging and delivery: Properly package the completed Golden Finger PCB to prevent physical damage or contamination. After completing the final inspection, deliver to the customer on time. Goldfinger PCB board production process requires high precision and strict control to ensure product quality and stability. We will operate in strict accordance with the above process to provide you with high-quality golden finger PCB board products.